Page 15 - Caswell Firesafe Manual 2018

P. 15

7 Fire Resisting Insulation

The requirement to include insulation on fire resisting ductwork should not be confused with the use of

insulation on standard DW144 ductwork systems. Insulation on DW144 ductwork is generally to prevent

condensation forming and / or retain heat in 'return air’ systems.

The purpose of specifically using fire resisting insulation is to prevent the ignition of combustible materials

in close proximity to a fire resisting duct due to radiant heat, which can be extreme under fire conditions.

During the fire tests (Ducts A & B) the surface temperature on the unexposed section of the ductwork is

recorded using 8 thermocouples; commonly known as the T1 & T2 thermocouples.

The speed of the temperature rise on uninsulated specimens demonstrates the importance of insulating the

ductwork where there is a risk of materials in close proximity being ignited through radiant heat.

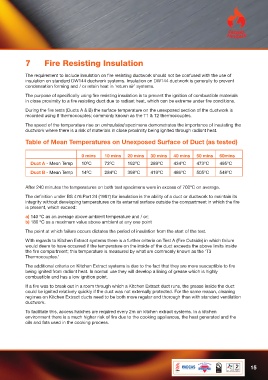

Table of Mean Temperatures on Unexposed Surface of Duct (as tested)

0 mins 10 mins 20 mins 30 mins 40 mins 50 mins 60mins

Duct A - Mean Temp 10ºC 73ºC 192ºC 289ºC 434ºC 473ºC 495ºC

Duct B - Mean Temp 14ºC 284ºC 398ºC 419ºC 486ºC 505ºC 548ºC

After 240 minutes the temperatures on both test specimens were in excess of 700ºC on average.

The definition under BS 476:Part 24 (1987) for insulation is the ability of a duct or ductwork to maintain its

integrity without developing temperatures on its external surface outside the compartment in which the fire

is present, which exceed:

a) 140 ºC as an average above ambient temperature and / or;

b) 180 ºC as a maximum value above ambient at any one point

The point at which failure occurs dictates the period of insulation from the start of the test.

With regards to Kitchen Extract systems there is a further criteria on Test A (Fire Outside) in which failure

would deem to have occurred if the temperature on the inside of the duct exceeds the above limits inside

the fire compartment; this temperature is measured by what are commonly known as the ‘T3

Thermocouples.’

The additional criteria on Kitchen Extract systems is due to the fact that they are more susceptible to fire

being ignited from radiant heat. In normal use they will develop a lining of grease which is highly

combustible and has a low ignition point.

If a fire was to break out in a room through which a Kitchen Extract duct runs, the grease inside the duct

could be ignited relatively quickly if the duct was not externally protected. For the same reason, cleaning

regimes on Kitchen Extract ducts need to be both more regular and thorough than with standard ventilation

ductwork.

To facilitate this, access hatches are required every 2m on kitchen extract systems. In a kitchen

environment there is a much higher risk of fire due to the cooking appliances, the heat generated and the

oils and fats used in the cooking process.

15